HELIUM LEAK DETECTION AT A FRACTION OF COST

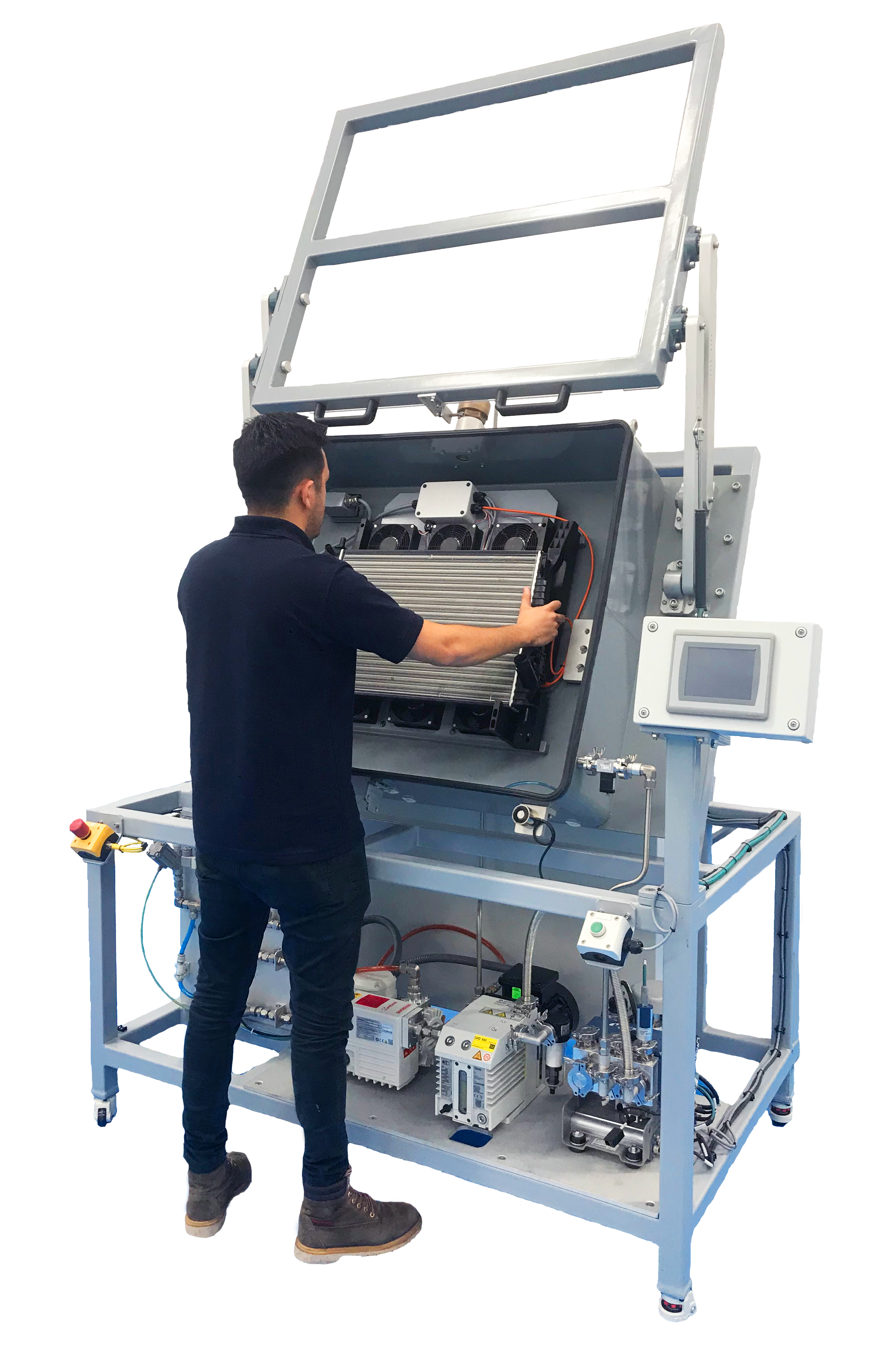

Accuro is a mass spectrometry leak detection system capable of repeatably finding leaks down to 1.0e-03 mbarL / s using helium or hydrogen.

It is a leak detection system that is not vulnerable to changes in temperature or volume which is a common problem in a pressure differential system and that generates false rejections causing high levels of scrap.

The Problem:

PERFORMANCE DIFFERENCE

There is a large gap in performance, repeatability and reliability between vacuum chamber leak detection machines versus all other leak detection solutions.

DIFfERENCe in price

The investment for a vacuum chamber leak detection machine is 6x against differential pressure solutions, and 4x against localized leak solutions.

THE SOLUTION, our Leak Detection System Accuro…

how does acurro work?

Why choose accuro?

Sensitivity

Accuro is capable of repeatably finding leaks down to 1.0e-03 mbarL / s using helium or hydrogen.

Automation

We automate the system according to your needs and budget. Either manual, semi-automatic or automatic.

repeatability

Accuro offers a Cpk of 1.45 which is higher than the minimum industry standard of 1.33. Even in products from a thermal process or that expand their volume during the test.

Flexibility

Accuro tools and tooling are easily interchangeable and the test chamber can be easily replaced to incorporate new products with different sizes.

safety

Emergency stops (Hardwired E-stops) in front and rear, access control for machine parameters in HMI. Pressure relief valves on all chamber and service lines.

CONTROLS OR TECHNOLOGY

PLC AB or Siemens with 20% scalability for I / O (I / O) assignment, 6 ”HMI Touch Screen, Traceability System, Industry 4.0 Add-ons.

KNOW HOW TO REDUCE YOUR SCRAP TO 50%

MAKE YOUR SYSTEM EVEN BETTER

AVAILABLE OPTIONS:

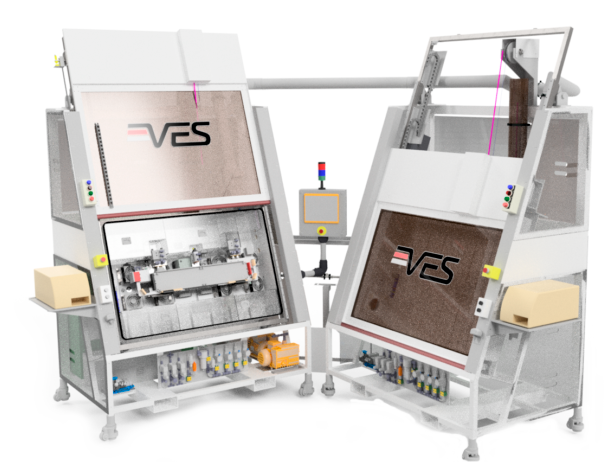

Double leak detection chamber

Reject hopper for defective product

Identification / marking system of good product parts

Barcode scanner and traceability

Automatic chamber door

Helium Recovery System

VESView – Web monitoring of your system

CASE STUDY

TESTING AUTOMOTIVE RADIATORS

Automotive radiators with a production demand of 60 radiators per hour, are tested in a pressure differential system at a leak rate of 4sccm to 2.5barA.

When installing the system, there were very high levels of rejection and inconsistency in the leakage values.

In order to improve the situation, the customer implemented a cooling area for the radiators prior to the leak test, installed a clean room around the leak machine, extended the leak test time, calibrations were performed on the system. every hour and the products that were rejected were retested.

By migrating to Accuro, the radiators could be tested directly at the exit of the welding process, the clean room was eliminated, the equipment is calibrated once a shift and the production of 60 pieces per hour was achieved with a double chamber system.

WE WORK WITH LEADING COMPANIES

They have already proven our quality and innovation

DO YOU HAVE A PROJECT IN DOOR? LET’S TALK

Whether you want to know more about Accuro or you already have a specific need in leak detection. Write to us and we will contact you in less than 24 hours.

«Accuro is the product of listening to our customers. It offers all the benefits of a vacuum chamber system at a fraction of the cost and is the best solution to products that come from thermal processes. Allowing to reduce waste, better utilization of factory space and lower labor costs. The machines are modular, flexible and ready for the future.»

Rodolfo Gutierrez

Managing Director – VES Mexico